Gasifiers

- Introduction

- Gasifiers Process Overview

- Down Draft gasifiers

- Updraft Gasifiers

- Applications

- Energy Calculator

- Model Price

- Photo Gallery

- Send Query

Biogas Plants

- Introduction

- Biogas Process Overview

- Bio Gas Types

- Industrial Solution/Agriculture Solution

- Calculator

- Model Price

- Photo Gallery

- Send Query

Gas Gensets

Gasifiers Introduction

Due to rapid industrialization and the burning of fossil fuels all over the world lead to emission of CO2. Contributes 50% of green gas emission

One of the remedies to limit the rising content of CO 2 in the atmosphere is energetic use of biomass fuel. Biomass is basically an organic material, which includes wood, crop residues, solid waste, animal wastes, sewage, and waste from food processing. Biomass is Your browser may not support display of this image. made up of mainly carbon and hydrogen.

Gasification basics

In this process, biomass is converted into a mixture of gases through a thermo-chemical reaction called producer gas consisting of combustible gases mainly hydrogen, carbon mono oxide and methane, non-combustible gases nitrogen, carbon dioxide and water vapor. The essence of gasification process is the conversion of solid carbon fuels into carbon monoxide by thermo chemical process. The gasification of solid fuel is accomplished in air sealed, closed chamber, under slight suction or pressure relative to ambient pressure This technology enables you to directly treat Green Wood / Biomass having moisture content of 10-15% without using a drying process.

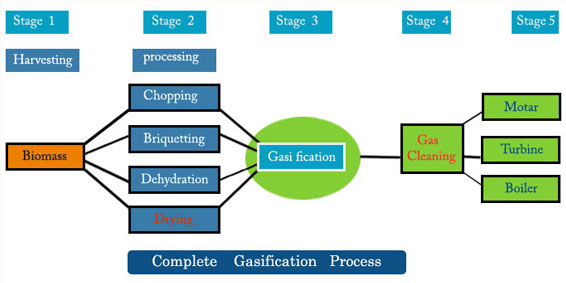

Biomass gasification is completed in many stages that elaborated and explained with a flow diagram given below

Your browser may not support display of this image.

Drying

Biomass fuels consist of moisture ranging from 5 to 35%. At the temperature above 100 o C, the water is removed and converted into steam. In the drying, fuels do not experience any kind of decomposition.

Pyrolysis

Pyrolysis is the thermal decomposition of biomass fuels in the absence of oxygen. Pyrolysis involves release of three kinds of products such as solid, liquid and gases. The ratio of products is influenced by the chemical composition of biomass fuels and the operating conditions. The heating value of gas produced during the pyrolysis process is low (3.5 - 8.9 MJ/m 3 ).

It is noted that no matter how gasifier is built, there will always be a low temperature zone, where pyrolysis takes place, generating condensable hydrocarbon.

Oxidation

Introduced air in the oxidation zone contains, besides oxygen and water vapors, inert gases such as nitrogen and argon. These inert gases are considered to be non-reactive with fuel constituents. The oxidation takes place at the temperature of 700-2000oc.

Heterogeneous reaction takes place between oxygen in the air and solid carbonized fuel, producing carbon monoxide. Plus and minus sign indicate the release and supply of heat energy during the process respectively

C + O 2 = CO 2 + 406 [ MJ/kmol]

In reaction 12.01 kg of carbon is completely combusted with 22.39 m3 of oxygen supplied by air blast to yield 22.26 m 3 of carbon dioxide and 393.8 MJ of heat.

Hydrogen in fuel reacts with oxygen in the air blast, producing steam .

H 2 + ½ O 2 = H 2 O + 242 [ MJ/kmol]

Reduction

In reduction zone, a number of high temperature chemical reactions take place in the absence of oxygen. The principal reactions that takes place in reduction are mentioned below.

Boudouard reaction - CO 2 + C = 2CO - 172.6 [MJ/kmol]

Water-gas reaction - C + H2 O = CO + H 2 - 131.4 [MJ/kmol]

Water shift reaction - CO 2 + H 2 = CO + H 2 O + 41.2 [MJ/kmol]

Methane production reaction - C + 2H 2 = CH 4 + 75 [MJ/kmol]

From above thermo-chemical reaction it may be understood that heat generated in pyrolysis is absorbed in reduction process. Hence, the temperature of gas which is very high in the beginning goes down as it passes through various stages. If complete gasification takes place, all the carbon is burned or reduced to carbon monoxide, a combustible gas and some other mineral matter is vaporized. The remains are ash and some char (unburned carbon).

Your browser may not support display of this image.

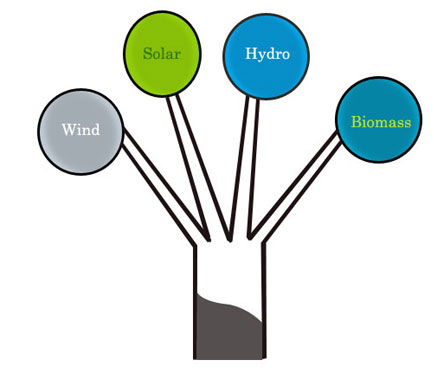

There are various renewable energy technologies available as shown in the Fig no.4 Each one has got its limitation such as, Wind power is cheap but is location specific & initial cost is high, Solar power is cheapest to generate but initial cost is very high, maintenance of batteries is an issue, Hydro power is location specific. Where as Biomass (Post Harvest Agri Residue) based power generation is not location specific, initial cost is not very high compared to other options available, running cost is cheaper. It is carbon dioxide neutral process hence environment friendly process. It can provide mass employment to rural masses if energy plantation is encouraged.

Your browser may not support display of this image.

Key Features :

• This Technology delivers Power Generation Efficiency up to 25 - 30% approx.

• Quick turn-down to 10%, for Greater Operational Flexibility.

• Fully Automated Operation - requires only few heads for maintenance.

• Waste Tar Water is cleaned with self-generated heat and can be released to public sewers.

• Ash has little residual carbon and no dioxin.

Copyright © Ascent Bio Energy. 2010.