Gasifiers

- Introduction

- Gasifiers Process Overview

- Down Draft gasifiers

- Updraft Gasifiers

- Applications

- Energy Calculator

- Model Price

- Photo Gallery

- Send Query

Biogas Plants

- Introduction

- Biogas Process Overview

- Bio Gas Types

- Industrial Solution/Agriculture Solution

- Calculator

- Model Price

- Photo Gallery

- Send Query

Gas Gensets

Bio Gas Types

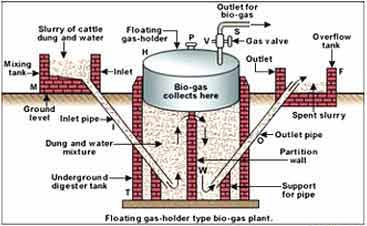

1) Kvic model (Floating Drum Model)

It consists of a deep well shaped underground digester connected by inlet and outlet pipes . a mild steel gas storage drum, inverted over the slurry goes up and down around a guide pipe corresponding to the accumulation and withdrawal of gas.

Benefits

- Capacity to maintain steady pressure of biogas by the movement of gas holder

- Inbuilt provision for scum breaking

- Volume of gas is known just by observing the position of the drum

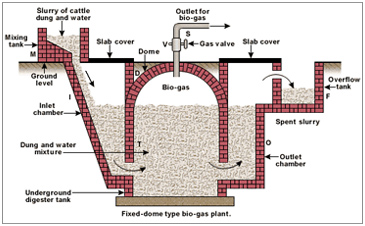

2) Fixed Dome

The main feature of this design is that the digester and gas holder are opart of composite unit made of brick masonry. It has a cylindrical digester with dome shaped roof and large inlet and outlet tank.

Advantages

- The plant is cheaper than the floating drum plants by 20-30%

3) Deenbandhu Model ( Fixed Dome Model)

It consists of a deep well shaped underground digester connected by inlet and outlet pipes . a mild steel gas storage drum, inverted over the slurry goes up and down around a guide pipe corresponding to the accumulation and withdrawal of gas.

Advantages

- The deenbandhu type costs about 20 % less than that that of janata model and 40 % less than the floating drum type of same size capacities

4) UASB UP-FLOW ANAEROBIC SLUDE BLANKET REACOR

UASB UP-FLOW ANAEROBIC SLUDE BLANKET REACOR is appropriate and economical process this type is used to treat waste water and for the production of biogas. The upward motion of released gas bubbles cause hydraulic turbulence that provides reactor mixing without any mechanical parts at the top of the reactor, the water phase is separated from sludge solids and gas in a three phase separator ( also known the gas-liquid –solids separator i.e. GLSS) .

Copyright © Ascent Bio Energy. 2010.